.png)

The solar panel cleaning

companion to

count on!

Introducing LOTUS-P4000, a semi-autonomous and waterless solar panel cleaning robot. It is an intelligent, worker-friendly, and economical solution for sharing a single cleaning robot on multiple solar rows. It comes with unmatched product quality and a remarkable ROI under 9 months for typical solar plants.

Upto 10% more generation output than bi-weekly cleaning

LOTUS P4000 cleaning system is based on ultra-soft microfiber cloths rotating along the length direction of the robot. The microfiber cleaning fins generate airflow and a controlled impact that flicks off the dust particles from the panels without any scratching or dragging.

Cleaning via airflow + flicking action

Up to 2 years of microfiber fins life

Easy microfiber replacement

Up to 98% cleaning in a single pass

Customizable brushes

Machine Design

Our attention to detail and support from IIT Delhi has resulted in a precision-engineered machine that delivers performance while consuming less power.

Patented Technology

We have patented our unique dual-drive system with real-time orientation control which helps to overcome the module irregularities upto 40 mm.

This aluminum and steel-made drive-unit is custom-designed to be strong and lightweight.

Materials

High-grade aluminum & stainless steel is used in parts and fasteners to achieve exceptional durability and corrosion-resistant product.

Motors

High-performance BLDC motors provide 5000+ hours of life under extreme conditions with high power to weight ratio and zero maintenance.

Frame

Our robots have a rigid open-body frame which doesn’t slack while lifting and produce minimal shading with stable operation under 50 kmph wind.

Precision Engineered

The precision engineered parts provide desired features of high strength and reliable operation while minimising the weight and power loss.

Our robots have passed multiple outdoor and indoor tests of 100 + hours of continuous-operations in IIT Delhi's facilities.

Outdoor tests

Indoor tests

.png)

Easy to handle and move

Carefully designed detatch-able handles provide row-shifting time as low as 25 secs while minimizing the weight of the robot.

Ergonomic design

Lightweight

Detach-able

25 secs row-shifting time

Maintains the SAFETY and INTEGRITY of solar PV module

-

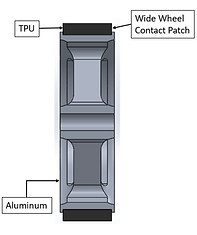

The wheels of the robot run on module frame to transfer the load from the frame to the underlying structure.

-

Microfiber cleaning fins flicks-off the dust and debris to prevent any damage to the Anti-Reflective Coating (ARC).

-

Appropriate hardness of the wheel coating material (TPU) provides cushion as well as durability.

-

In-lab simulations result in a Factor-of-Safety (FOS) value of 5.62.

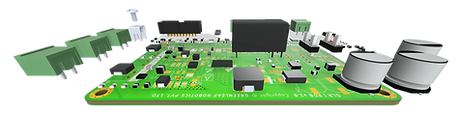

All robots are equipped with automotive grade electronics

and 4G based communication

system

Performance

- ARM Cortex M4 based processor

- 4G LTE communication system

- Low current consumption

- High-endurance parts and switches

- Noise & Interference cancellation design

- Advanced firmware

Safety

- Automotive grade Q1 components

- Extended temperature operation

- Over current & voltage protection

- Lightning surge protection

- Impact-resistant enclosure (IK 07)

- RoHS and CE certified parts

- IP65 ingress protection

Longer cleaning time with lesser battery size

With a swappable and high energy-dense lithium battery pack, the cleaning never stops!

A single cleaning cycle of standard 1 MWp solar plant is done under 2.5 hours!

Upto 4 hours

of cleaning time with

12Ah @ 25.6V (Std. range)

Upto 6 hours

of cleaning time with

18Ah @ 25.6V (Exd. range)

The Charging Point

Solar-based charging points are installed at designated points on the site to charge the robots’ batteries, thus achieving true energy independence.

_JPG.jpg)

Solar-based charging

Full charge under 2 hours

Charges multiple batteries

Set-up at any location

Fast installation

All weatherproof

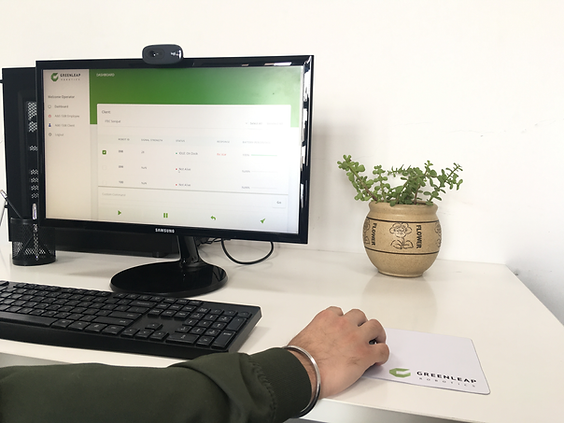

Dashboard

Real-time monitoring

Error notification

Report generation

Tier-1 Suppliers

Approved By